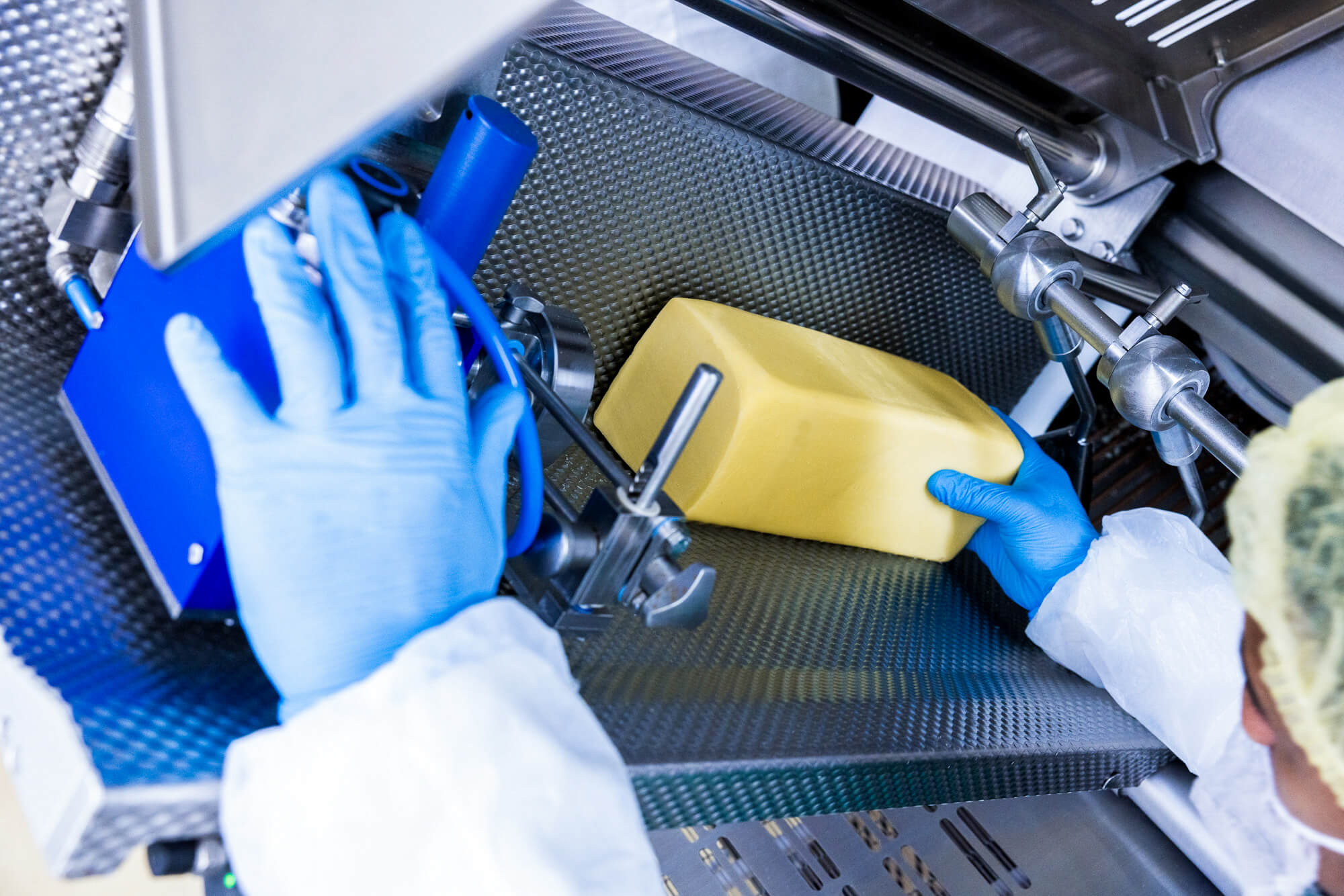

Devices & Facilities

Inspection systems

Protect yourself from recourse claims and image damage: Bizerba inspection systems automatically ensure that your products leave your house in the best quality. Our inspection systems are tailored to the respective needs of the food, pharmaceutical and chemical industry. Metal detectors, vision inspection systems, X -ray inspection, checkweigher - we have the right solution for your products.

Any questions?

Please contact our specialists at any time

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again