A fresh mix for your success

Finding, not searching

Adros & Bizerba: A partnership based on safety and precision

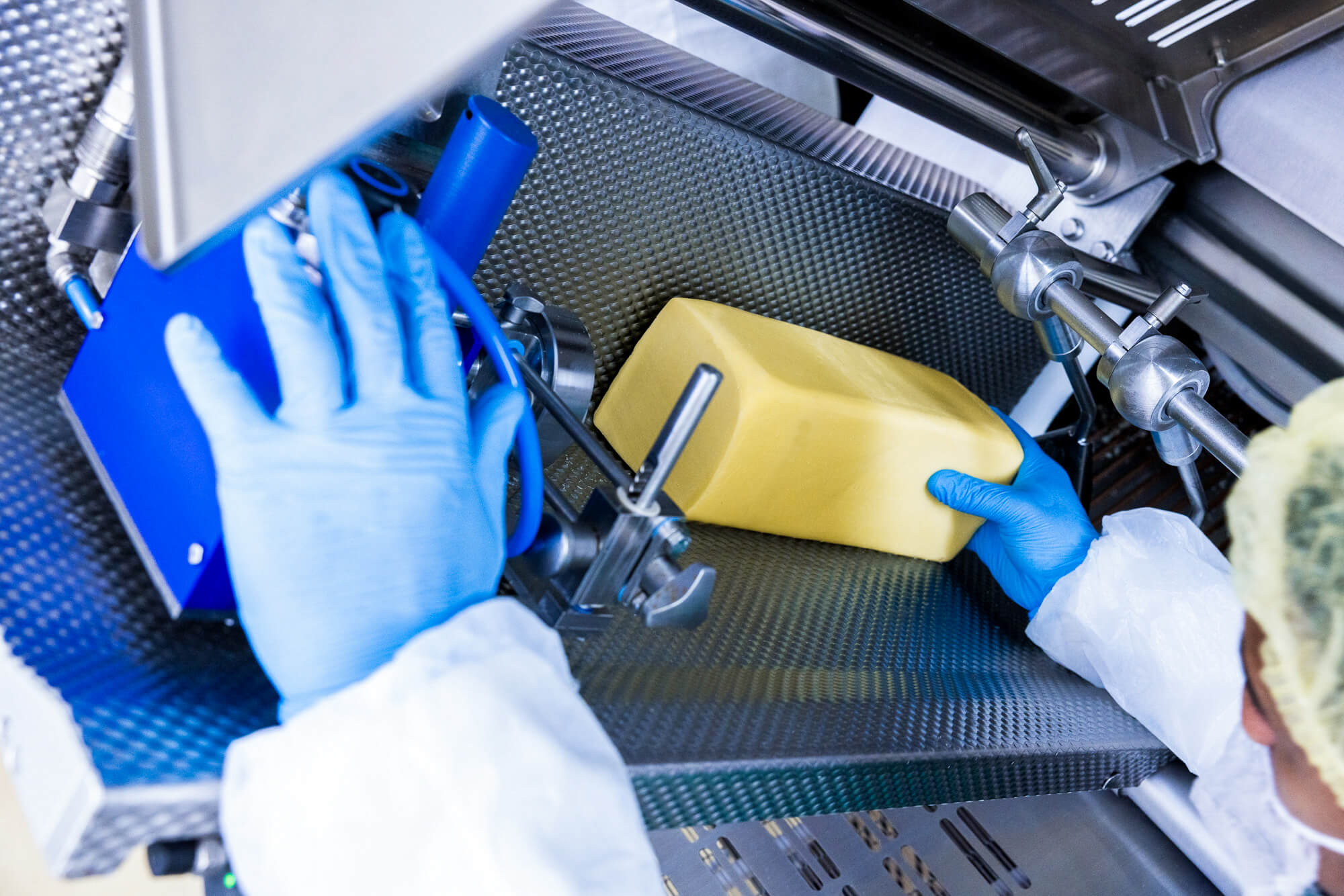

Adros is one of the most modern poultry processing plants in Poland. The company’s roots go back to the 1970s, when the Borowski family established its first farms. Since 2002, the Adros abattoir has expanded steadily, investing in modern equipment and technologies and developing into a major chicken producer in Europe.

Modernize your butcher shop with intuitive weighing and traceability solutions

When it comes to seamless traceability, high performance and customer experience, digital tools play a key role in the food retail sector. In this testimonial, Kilian Leduc, Butchery Manager at E.Leclerc Trélissac, France, shares his experience using intuitive weighing and traceability solutions designed to simplify the daily tasks of his teams and meet consumer expectations.

Smooth & smart operations at E.Leclerc, Trélissac: Optimizing the prep room and counter

Connected scales at the fish counter at E.Leclerc, Trélissac, France

One of the distinctive features of E.Leclerc stores in France are the large fish display cases with a wide range of fresh fish and seafood. This is very attractive to fish lovers and a profitable offering for retailers - provided the equipment allows efficient processes and central control in all departments. Bizerba offers connected, precise and durable scales for every retail sector that can be managed in the back office. This is exactly what E.Leclerc needs for its fish outlets.

Compact production line for natural sliced cheese

High quality, practical, tasty and healthy: Ladismith Cheese makes natural cheese competitive

From long lines to fast lanes: speeding up the deli counter

Slovakia’s oldest cooperative retail network streamlines deli counter service with intelligent slicing technology from Bizerba.

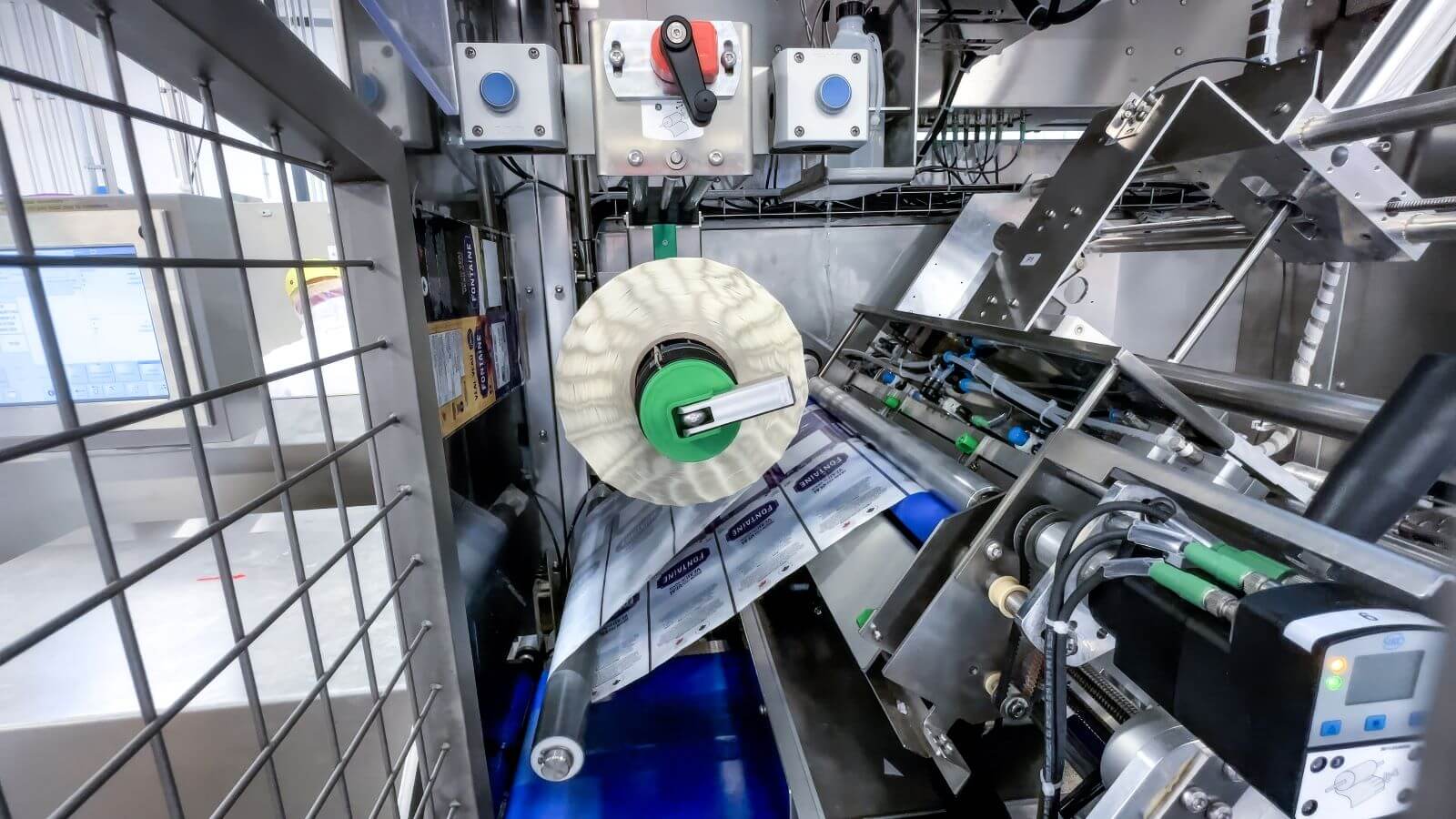

Bird Brothers optimizes packaging efficiency with C-Wrap labeling

To maintain high standards in packaging and meet the demands of a growing market, Bird Brothers, a major UK egg producer, modernized its labeling process. With the integration of the GLM-I 120 C-Wrap labeling system from Bizerba, Bird Brothers has enhanced reliability, product presentation and operational flexibility while reinforcing its longstanding commitment to quality and innovation.

Everything under control with MyBizerba

OSM Kosów Lacki and Bizerba: 100-year tradition supported by modern technology

OSM Kosów Lacki has been producing cheese, cottage cheese and butter of the highest quality for nearly 100 years. It combines tradition with modern Bizerba systems to support its production and labeling processes.

Our path to security excellence

Today's security threat situation is complex and multi-layered - characterized by global risks and digital challenges. Political tensions, economic uncertainties and digital attacks on companies are becoming increasingly intertwined. Cyber attacks have long been a strategic corporate risk: they threaten networks, supply chains, production processes and critical infrastructures.

This specialist article sheds light on the causes and consequences and shows how Bizerba is strengthening its future viability through prevention, resilience and collaboration.

A historic collaboration for a tailor-made and committed solution

Soly Import expressed the need to promote a new premium avocado sold individually. The objective was to offer packaging that was both attractive and compostable.

Büyüksimitci Et: tradition, accelerated

A scale as a statement piece

Tea is a high-quality product where every gram counts. You might think that a specialist shop like Helmut Volkmann's would therefore rely on state-of-the-art digital weighing technology. Far from it! Volkmann trusts his old Bizerba tilt scale, which not only works as precisely and reliably as a Swiss watch, but is also part of his company philosophy.

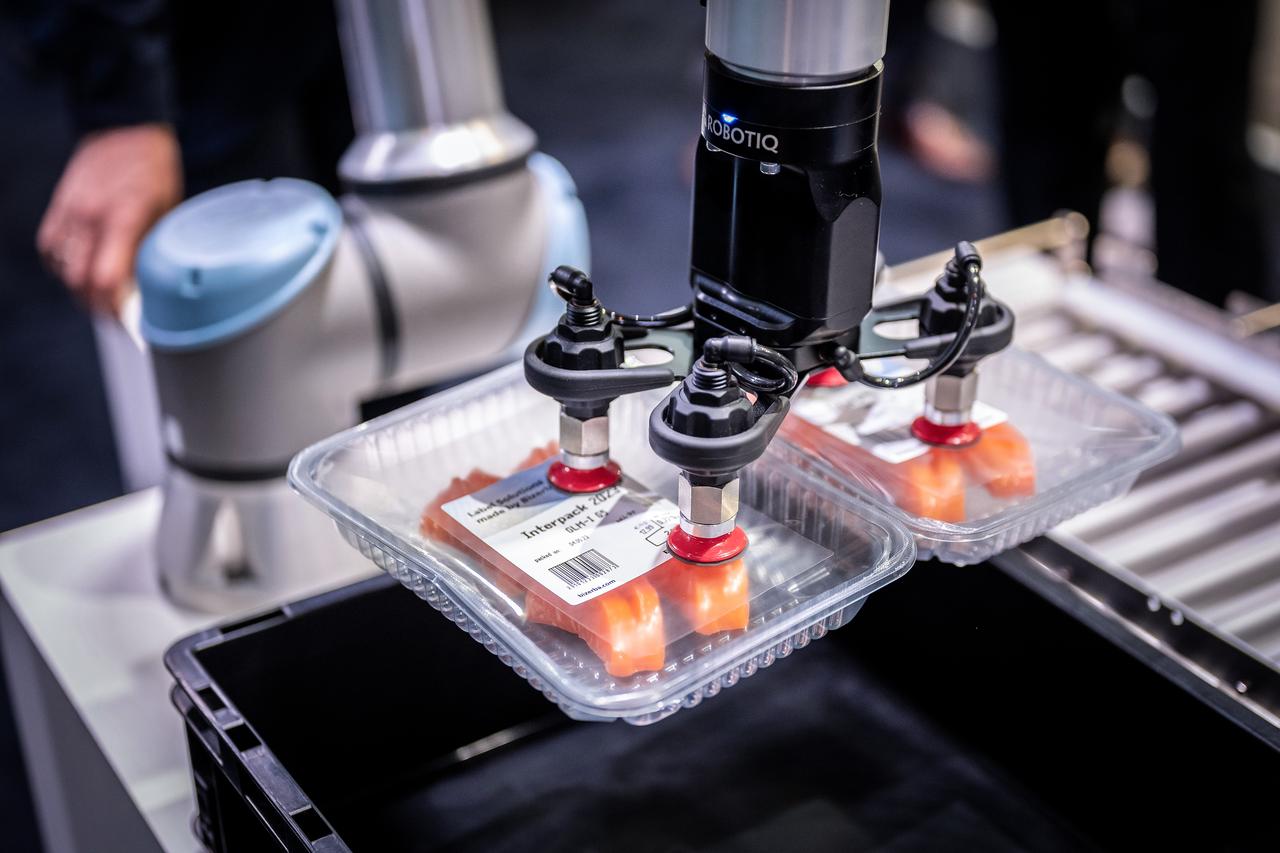

Automation is not an end in itself

How is automation changing the food industry? Why is robotics not a contradiction to traditional craftsmanship - but a lever for sustainable quality? The two experts Eduard Schirling and Oliver Deifel from the Retail and Industry business units talk about technical solutions, sector-specific challenges and their personal drives.

Bringing home the bacon: efficient, automated processing at Fumagalli

Robots don’t replace people. They relieve them.

Production lines in the food sector are reaching their limits. High quality requirements, fluctuating order volumes, and a shortage of skilled workers make the end-of-line process a critical bottleneck. Oliver Deifel, Director Global Customer Solutions & Integration Business at Bizerba, explains how modular automation solutions can help – and what companies should keep in mind when getting started.

Sealing success: inside Kraft Heinz’s new vision inspection system

To protect product quality, optimize production and reduce costs, Kraft Heinz partnered with Bizerba to implement an advanced vision inspection system at its Kitt Green site in the UK. The result? A custom-engineered, seamlessly integrated seal inspection solution that’s reliable, easy to use and making a huge impact from day #1.

Hybrid fresh food counters: efficiency meets flexibility at the POS

Retailers are facing new challenges at the fresh food counter—from rising labor costs to changing customer expectations. Hybrid counter concepts aim to solve both. We spoke with Alexander Pogacnik to learn how the combination of on-demand slicing and integrated packaging technology is reshaping operations, improving hygiene and supporting flexible in-store strategies.

Self-Checkout & Self-Scanning: Efficiency, Security and Innovation in Food Retail

Self-service systems are becoming increasingly important in food retail. But what do terms like self-checkout and self-scanning actually mean in practice, and how can retailers benefit from them? We spoke with Maximilian Ast to learn more about the current developments, underlying technologies and what the future holds.

Automated meat processing at Fümeci Smokehouse

Discover how Fümeci Smokehouse in Istanbul partnered with Bizerba to implement a fully automated slicing, weighing, packaging and labeling solution. Precision, efficiency and food safety in one line.

CSP meets the increased demands of the Koch artisan bakery

Modern slicing technology for bakeries enables efficient sales and a relaxed café experience.

Leak detection redefined: How LeakSecure is raising food safety standards

We speak with Carole Besnard, Product Manager for Machine Vision at Bizerba, to discuss the latest innovations in automated leak detection for food packaging. Carole shares insights into how LeakSecure, an advanced in-line inspection system, is helping food producers ensure packaging integrity and extend shelf life—without slowing down production.

By combining precise CO₂ leak detection with seamless integration into existing lines, LeakSecure is designed to tackle today’s toughest challenges in food safety and quality control.

Everything flows

Constant change is the best way to describe the rapid evolution of e-commerce. The industry cannot afford to stand still if it is to meet the still strong growth forecasts. André Weibrecht understands the challenges his clients face from every angle - both professionally and personally.

A special find in Trento, Italy

You don't have to look for old Bizerba treasures, they find you. Just like this table scale, which is waiting for its new owner on an oil drum between old lawn mowers. Our colleague Massimo Cremonesi came across this special find during a walk in Trento.

Fast, accurate, safe: AI-supported weighing at SPAR South Africa

Incorrect registrations on self-service scales lead to a loss of sales, while staff are tied up in the fresh food areas and the shopping process is delayed. At SPAR, AI-supported scales solve several problems at once and make shopping smart and convenient.

Augmented support in action: how digital tools increase service efficiency

We speak with Frank Steinlehner, service expert at Bizerba, about how augmented reality is changing the way technical support is delivered. With the Augmented Services app, Bizerba connects experts and customer technicians via live video, interactive tools and 3D digital twins. Frank explains how this approach not only speeds up troubleshooting and spare part identification but also helps reduce downtime and increase productivity across a wide range of service cases.

Specialty cheese store Fromagerie d'Austerlitz

For his Fromagerie d'Austerlitz in Lyon, Managing Director Jérémy Richard needed a customized, particularly flexible weighing solution for the cheese counter. After all, the appliances should be easily adaptable to new conditions following the upcoming renovation of the store. The PC scale K-Class Flex with its modular design was the right solution for this requirement.

Bidfood: Maximum throughput and optimum hygiene

One example is the use of the latest weighing and labeling technology at the production facility in Kralupy nad Vltavou.

Why it is important to calibrate your scales annually

Find out why annual calibration of your scales is essential for accuracy, customer satisfaction and regulatory compliance. Read about the benefits and how to avoid risks for your business here.

AI-driven scales: reducing queues and improving accuracy in supermarkets

We speak with Wendell Trican, a Technical Solution Expert at Bizerba, to explore how artificial intelligence and object recognition are transforming fresh food sections in supermarkets. Wendell explains how AI-enabled scales can now automatically identify items placed on them, generating labels instantly and reducing the need for staff assistance. With self-learning capabilities, these scales promise a faster, more efficient shopping experience by cutting down queues and improving accuracy.

Visually attractive product presentation and good working conditions for employees

With the help of long-standing technology partner Bizerba France, manager Antoine Gandolfi was able to efficiently automate tray labeling and banding.

Maximum food safety for baby nutrition

Product safety is a paramount concern in the food industry, particularly in the production of baby food. Having previously used metal detectors to remove common contaminants, the company has now enhanced its safety protocols by integrating an advanced X-ray inspection system into its new production line.

Weigh price labeling reimagined: the new GLM-I series in practice

We speak with Florian Stifel, product expert at Bizerba, about the increasing complexity in food production and how the redesigned GLM-I series helps producers adapt. As production lines grow while physical space remains limited, manufacturers need more flexible and efficient solutions. Florian explains how the new GLM-I weigh price labeler meets these demands—offering a modular design, faster print speeds, easier maintenance and full digital integration for centralized control via the BRAIN2 software suite.

Blending heritage with slicing innovation

Improve logistics and industrial processes with RFID tags

These challenges can save companies millions, for example in logistics. Whether it's classic handling or goods tracking—RFID tags are indispensable when it comes to efficiency, traceability and fraud prevention.

Berry market leader automates labeling

Qualitas Berry's blueberries are meeting with growing international demand - around 80 percent of the annual production of up to 600 tons is exported. Due to the sharp increase in throughput, manual weighing and labeling threatened to become a bottleneck in the otherwise highly automated production process.

Sax butcher's shop fulfills the wishes of tomorrow's customers

Traditional butcher Sax is a regional supplier in Baden-Württemberg, Germany. In order to better meet the changing needs of his customers, owner Franz Sax set up a self-service area in his main store and introduced self-scanning checkouts. The future-proof concept required technical modernization, for which Bizerba provided comprehensive support.

Craftsmanship meets high-tech

Some call it connected commerce, others call it the perfect customer experience: With the help of the Bizerba RetailApp MyOrder, among other things, the innovative traditional butcher Mühlenbeck creates a consistent and continuous shopping experience - whether in the store or for pre-orders via app or phone. This also includes networked Bizerba hardware that integrates seamlessly into the existing infrastructure, whether in production, in the preparation room, at the fresh food counter or at the cash register.

Passion for Bizerba old-timers

Time and again, we discover lovingly maintained Bizerba inclinometers from the 50s and 60s with our customers. Claudio Pontarollo, owner of the Hotel Hamann in Balingen, has a special passion for these elegant devices. Not only does he display them in the window of his RISTORANTE "La Galleria", he even has a mini-collection in his cellar. And even in the kitchen nothing works without the classic appliances from Bizerba.

At sea with mobile precision

Meet Anneke, a passionate Dutch fishmonger from the picturesque fishing village Yerseke at the North Sea, who is now using the Bizerba fish scale Q1 400 to modernize her traditional fish stand. In our interview, Anneke tells us how the mobile and precise scale is helping her to make changes in her daily routine and improve the service of her mobile fish stand. Read how this new fish scale is changing the way she runs her family business, maintaining old traditions while embracing new technology.

Tradition meets technology

The discussion about the use of slicing machines instead of traditional knives is taking place against the backdrop of current trends in the food service industry. Adaptability, data control, sustainability and creative approaches are currently at the forefront. Master Li from Chaoshan and Chef Moreau bring their expertise to a context characterized by rising food prices, health crises and growing environmental awareness. While Master Li highlights the importance of traditional techniques, Chef Moreau emphasizes the benefits of automation, bringing efficiency and sustainability to the modern kitchen.

How Bizerba slicers support the delicatessen business

Where perfection is non-negotiable, you will find Bizerba machines. In particular, we found our slicers in the delicatessen store of Antonio Schillinger in Merano. Here, dried ham such as South Tyrolean speck and prosciutto crudo are transformed into perfect slices. We met Antonio for a brief chat.

Attractive, economical, and sustainable packaging solutions for Montpak

To meet rising demand, Montpak, a Canadian specialist in veal and lamb meat, must automate its processes. The fully automated GLM-Ievo labeling system, equipped with Bizerba CleanCut® technology, meets the stringent requirements of this quality-driven, environmentally conscious company.

The long way to the scale

Almost 10% of the world's population is physically or mentally impaired. Their everyday lives are fraught with challenges. Regular shopping is particularly difficult for wheelchair users or people with dysmelia.

Modern retail concepts such as smart or self-service supermarkets now have the opportunity to make the most normal thing in the world - grocery shopping - easier.

We would like to thank Henry Idiri from Berlin for the brief interview.

Self-service scales with object recognition

Self-service scales with AI-supported object recognition solve several problems in fruit and vegetable self-service areas. Thanks to artificial intelligence and cloud technology, detection accuracy is increasing every day – find out how.

Meat slicers make around 30 hotpot restaurants more efficient

In view of these dimensions, Niuzong Dian had considerable potential for increasing efficiency when slicing beef. More specifically, yellow beef – the most important ingredient in the hotpot variations on offer.

Classic weighing at the Vongerichten Winery and Guesthouse

Bizerba stands for quality and longevity. This is why we meet customers again and again who have been slicing or weighing with Bizerba for decades - such as the Vongerichten winery, for example, which has been relying on the precision of the Bizerba inclinometer for weighing delicatessen products since the 1960s.

The Greek Farmer expands into new distribution channels

British charcuterie brand The Greek Farmer appeared on the Channel 4 series "Aldi's Next Big Thing". Having won a contract with the supermarket chain, it now has to think in completely new dimensions and deliver 15,000 cold cuts as quickly as possible. With the VS12 D automated vertical slicer from Bizerba, this can be done successfully.

Kantine Offenburg consistently serves top-quality sandwiches.

Say goodbye to pre-portioned depositing – Kantine Offenburg prides itself on topping bread with freshly-sliced meats. This is thanks to the GSP HD automatic diagonal slicer. All employees can use it to prepare sandwiches of consistent quality quickly and without food waste.

Craftsmanship with industrial throughput

Delicio's specialities include traditionally made meat products, which are increasingly in demand. How can the company produce faster without compromising the authentic character of its products? A new slicer is the solution.

Fine dining and sustainability for the Rust en Vrede Restaurant

Chef Fabio Daniel sought to find the right equipment in his fine dining restaurant to prepare food that would deliver precise results, produce less waste, and make a detailed statement. Bizerba's solutions for food production were just what he was looking for.

Safety and reliability at the end of the production process

Automating the end-of-line area increases the profitability of manufacturing companies and solves staffing problems. Smaller companies in particular, though, need flexible solutions – for example, when different goods are produced or human intervention is needed from time to time. The Bizerba end-of-line solution meets these requirements. It is open, flexible and scalable and allows full control of the production process. High-quality Bizerba components ensure reliability and low operating costs.

Preventing revenue losses: fraud prevention at the self-service scale

A wide variety of technologies based on innovative process automation and digitally supported shopping experiences are booming in the stationary retail sector. In particular, networked retail solutions featuring artificial intelligence (AI) are growing in popularity. AI-based self-service scales with object recognition in the self-service are of the convenience store are just one example.

Butcher shop Metzgerei Mengis uses digital retail scales to upgrade their sales counter

To meet fiscalization requirements, Mengis, a family business, invested in new Q1 retail scales from Bizerba. The practical models help them satisfy the latest hardware and software standards for cash register systems, digitalize their operating procedures, while the streamlined design also saves space at the counter.

Connected slicers at the fresh food counter: Smarter Slicing for more efficiency

We speak with Alexander Pogacnik, technical expert at Bizerba, about how connected slicers are improving operations at the fresh food counter. Long queues and uneven machine use are common challenges in retail. With real-time data and intelligent indicators, retailers can optimise workflows, reduce waiting times and improve availability. Alexander explains how “Smarter Slicing” helps staff in their daily tasks while giving the back office the insights it needs to manage equipment more efficiently.

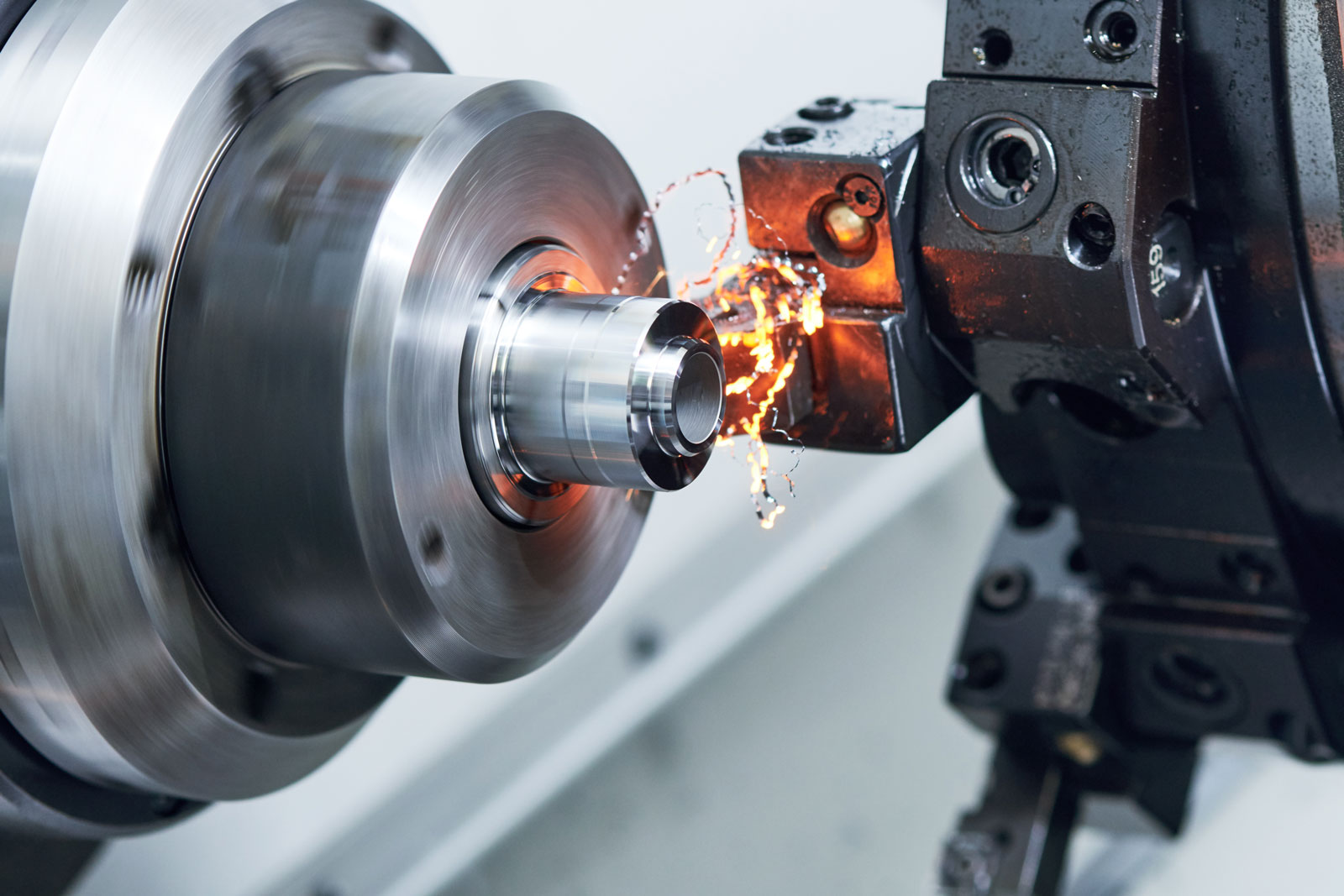

Producing and delivering more efficiently with Bizerba

Weight-based counting thanks to the networked Bizerba solution: Richard Weiss produces 0.5 billion precision turned parts every year, and production transparency is essential.

Cost control: what are the actual costs of your machinery and plants?

Recognize hidden cost factors and invest smartly with life cycle costing

Vimco incorporates Bizerba technology at cookie manufacturer

From molding and cartoning machines to wrappers: As a machine manufacturer, Vimco focuses on packaging solutions. As a system integrator, the company also offers complete packaging lines and relies on third-party systems. On behalf of a Croatian cookie manufacturer, Vimco implemented a solution incorporating Bizerba weighing and inspection technology.

Market for smart load cell systems has plenty of potential

Bizerba has now also become a sought-after OEM partner in the load cell technology sector. We produce and develop customized solutions as components for smart systems on behalf of our customers. As an example: WS-MiniSlim, a particularly compact weighing technology solution for weighing rack systems, giving the customer the ability to continually monitor their available stock levels.

15 % more productivity through connected solutions

Traditional manufacturer of premium jams optimizes quality control, efficiency and traceability through a comprehensive new quality management system.

Only the label makes a brand a brand

What parts do labels play in a purchasing decision? What makes a label? And what makes Bizerba labelling solutions? About the meaning and opportunities labels have for building a brand, and what Bizerba offers its customers.

Four nightmares for food producers

Food safety remains a challenge – as shown by the high number of around 12,000 product recalls annually in the EU alone. From illegible labels to missing allergy information, from contamination due to foreign particles to sealing seams that are not leak-tight: What can manufacturers do to minimize risks? Here is an overview of labeling and inspection solutions that help automate the separation of faulty products.

.jpeg)

Digital Services – Less dependency on time and space

They function reliably without on-site intervention and are available around the clock. This makes digital services unbeatably fast and economically appealing. Just one of many reasons why more and more companies are turning to them – including Bizerba.

A vitamin boost in the production area of the produce giant

Precise weighing and labeling is essential in the food industry. Wherever these processes are subject to errors or are too labor-intensive, they quickly become a bottleneck in production. Furthermore, economic damage can be the result of incorrect weight information on food packaging, for example. With a weighing and labeling solution from Bizerba, Nature's Pride, the produce giant, took weighing and labeling to a whole new level.

There is no content here yet

We are working flat out to develop exciting and informative content for your needs. Please visit this page again soon

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again