Inspection systems prevent errors reliably

Inspection system manufacturers play an essential role in helping businesses plan with confidence. State-of-the-art machines such as metal detectors or X-ray devices are able to detect contamination by foreign bodies like plastic, metal, and glass in products.

But not every defect or contaminant can be detected easily: detection accuracy depends heavily on the so-called “product effect”. For example, products with high moisture content, high salt concentration, or strong electrical properties can affect detection accuracy. Nevertheless, modern inspection systems represent an important step toward guaranteeing maximum food safety.

Control is good—Inspection is better

Consumer confidence is paramount—customers want to be sure they can enjoy their goods without hesitation. That’s why end-to-end quality management is essential for food production companies. Our inspection systems use the latest technologies to detect and eliminate risks, ensuring our partners can deliver high-quality and non-contaminated products.

Product recalls and complaints prevent your business developing and stop you reaching your goals. At a time when health and safety is of utmost importance, our key aim is to guarantee the highest standards for your products, allowing you to manage your business with confidence and consumers to enjoy your products without concerns. Because you can rely on us to stop what’s stopping you—and avoid product recall disasters for your business.

Optimizing processes, making the production more efficient

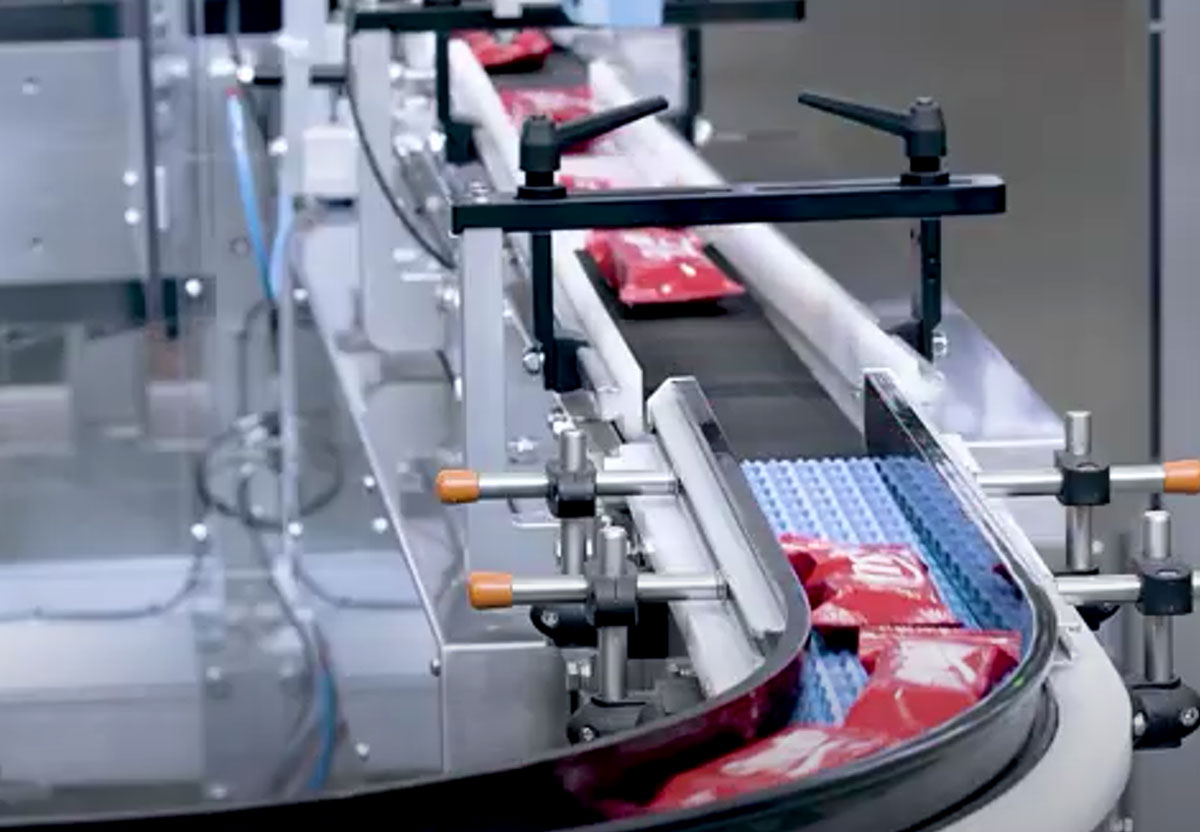

Inspection systems with dynamic checkweighers from Bizerba are an essential investment for food manufacturing companies in order to achieve their business goals. The Bizerba portfolio ensures easy-to-integrate solutions that optimize your existing processes and make them more secure—and everything by fitting into your existing production line. As a result, your company can focus on its core competences and continue to work on its economic development.

Read the following case study that shows how an inspection system including a dynamic checkweigher with integrated search coil turned out as the perfect solution for a pastry packaging line that required a combination of high throughput and a maximum reliability of avoiding food product contamination:

Ready for anything with Bizerba dynamic checkweighers

The example of Bizerba's CWDmaxx checkweigher shows that this is not only an investment in product safety, but also in making your business ready for the future: it weighs products from 10 g to 3,000 g and can be used with up to five belt modules thanks to its modular design. It includes quality assurance features such as metal search coils, various rejection systems, and flexible configuration options for existing production lines—because inspections systems should integrate seamlessly with hardware and software alike. With enough memory to save up to 100,000 items and smart, user-friendly operation, it’s perfect for networking all your systems. Play it safe with our smart checkweighing inspection solution—with maximum precision, reliability, and updates for long-term system stability.

Furthermore, when developing solutions for your company, we put a special focus on your employees in production and logistics. Safety at the workplace, facilitating usability and the sustainability of our inspection systems are fundamental components of each of our designs. Highly trained specialists who can concentrate fully on their tasks are a company’s most valuable assets. And because we know how important support systems are for a job where there is no room for error, we are always thinking one step ahead—so you are always one step ahead of the competition.