Its products include fish, meat, game, frozen meals and ice cream, as well as cold cuts, sous-vide products, breaded products, puff pastry, croquettes and frozen fruit and vegetables. 65% of Bidfood's products are sold to institutional kitchens, restaurants, hotels, canteens, retirement homes, hospitals and others. The retail sector, which is an important growth segment for Bidfood, accounts for the remaining 35%.

- Started in 1990 as a commercial agency of Nowaco

- 5 production sites in the Czech Republic

- 65 % sales in the food service sector

- 35 % sales in retail

- 1.2 kg of Bidfood products are bought by each Czech on average every year

More about Bidfood

Bidfood's customers appreciate not only the quality of the products, but also the service that the company offers. This includes the company's own catering studio, where it regularly organises courses for professionals. These include training seminars on new legislation (new consumer baskets for school canteens) or specific raw materials (fish, meat, cured meats). There are also popular cooking courses led by top chefs from the Czech Republic and around the world, where participants can find inspiration. The Gastro Studio is headed by chef Marek Svoboda, the only certified WACS representative in the Czech Republic.

Bidfood strives to keep up with the latest trends and technologies in order to offer innovative and attractive products. The company also places great emphasis on ecology and uses recyclable materials in its production to minimise its impact on the environment.

Saving time and resources

Manual labelling is time-consuming and labor-intensive, and at Bidfood, it could only be done on the top of the pack. When the company entered the retail market, it needed a much faster and more flexible labelling process. In addition, the packaging had to be labelled on up to three sides - on the one hand for the legally required information and on the other hand for the high-quality branding of the Bidfood brands and the private labels of the retailers supplied.

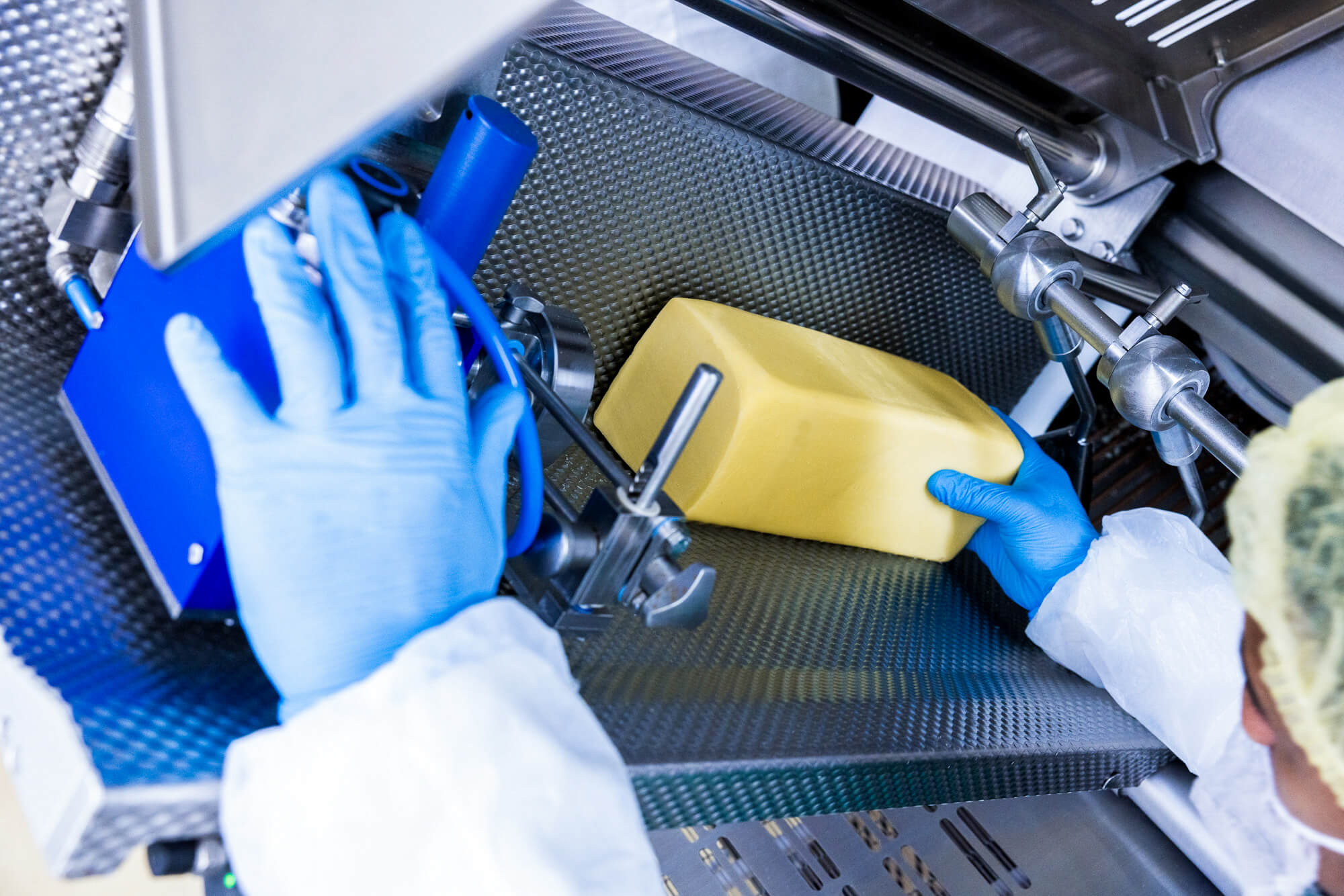

The company was therefore looking for a solution that could weigh and label in a single step, with one to three labels applied simultaneously. This was crucial for Bidfood's competitiveness in the retail chain market. Thanks to the Bizerba labelling systems, the company is now in a position to meet the legal requirements and to present its own brands Nowaco and Gurmet as well as the private labels of the retail chains in an attractive manner.

Suitable Weighing and Labelling Systems for All Products

Bizerba weighing and labelling systems are in use at nine lines at five Bidfood production sites. The solutions are integrated into Bidfood's central product database. The product database talks to the Bizerba database.

Automated end-of-line labelling

"These labelling systems are now the core of our automated lines. "They're the last step before the goods are put in the cartons," says Operations Manager Jan Kanina. "We changed the process for minced meat too," he says.

Precisely portioned minced meat

The minced meat line aimed to prevent incorrectly weighted packaging from leaving the plants. Secondly, to prevent incorrect weights from being packaged unnecessarily. Bizerba checkweighers and software for controlling the filling system have saved Bidfood a lot of packaging material. This has saved money and is good for the environment. Additional benefits: The entire process is automatic and hygienic.

Future-proof thanks to extra capacity

Bidfood produces 175 tons of fish and meat per month on Bizerba machines. The company has bigger plans. Plant manager Kanina said, "The packaging systems can process up to 30 ppm of fish today. The Bizerba systems aren't working at full capacity. This extra capacity will let us meet future demand. We just need to change the upstream processes."

Larger orders, freshest quality

Jan Kanina is happy with the results of the automation. "Automation lets us produce large orders quickly. This creates new opportunities in catering, canteens and retail." The faster throughput helps maintain product freshness. He appreciates Bizerba's proximity, reliable service, excellent technicians, and open communication. This communication was important to him, especially with Aleš Voit from Bizerba Sales.

Let’s Count

The Bidfood solution

Downloads

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again