Food Warnings: Figures and Causes

The FSA identified the most common causes of recalls as:

Undeclared Allergens (57 cases): These were primarily due to labelling omissions from recipe changes or cross-contamination.

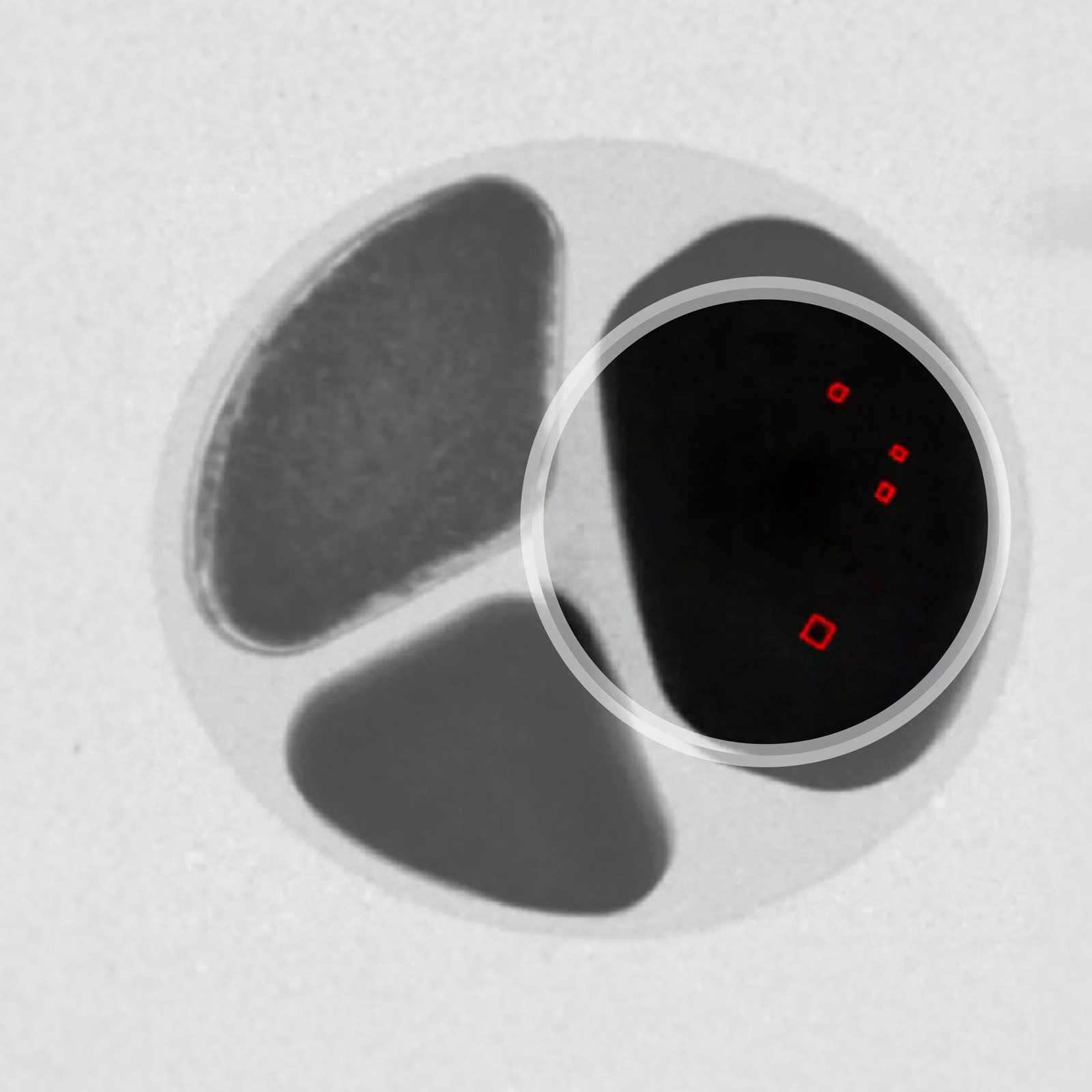

Physical Contamination (23 cases):This includes foreign materials such as metal or glass entering food during processing.

Pathogen Contamination (22 cases): Bacterial contamination resulting from inadequate hygiene or improper storage conditions.

Incorrect Use-By Dates (7 cases): Errors related to labelling or product coding.

Additional issues include cross contamination, counterfeit products in the supply chain, and defective packaging. Such figures underline the importance of robust quality management throughout the food industry.

Furthermore, the United Kingdom Food Security Report: Theme 5: Food Safety and Consumer Confidence, published on December 11, 2024, highlighted that approximately 26% of all incidents reported over the past three years involved microorganisms that could potentially cause illness. The report also noted an upward trend in food businesses' hygiene compliance, although a backlog of businesses still awaits inspection.

The Consequences for Companies

A recall can have far-reaching consequences for companies, from economic losses to a loss of consumer confidence. In addition to direct costs such as the recall and disposal of affected products, there are also indirect costs, such as production downtime or loss of reputation.

In an increasingly digitalised world, information about recalls is being disseminated faster and more transparently.

Secure Supply Chains as a Solution

Secure supply chains play a key role in minimising the risk of contamination and recalls. Traceability is a key aspect of this. Modern systems make it possible to precisely identify affected batches and recall them in a targeted manner instead of withdrawing entire production series from circulation. This reduces costs and maintains consumer confidence.

Technologies such as metal detectors, X-ray systems and visual inspections help to identify and reject foreign bodies at an early stage. Supplemented by digital solutions, such as the integration of GS1 Digital Links on packaging, transparency is improved across the entire value chain.