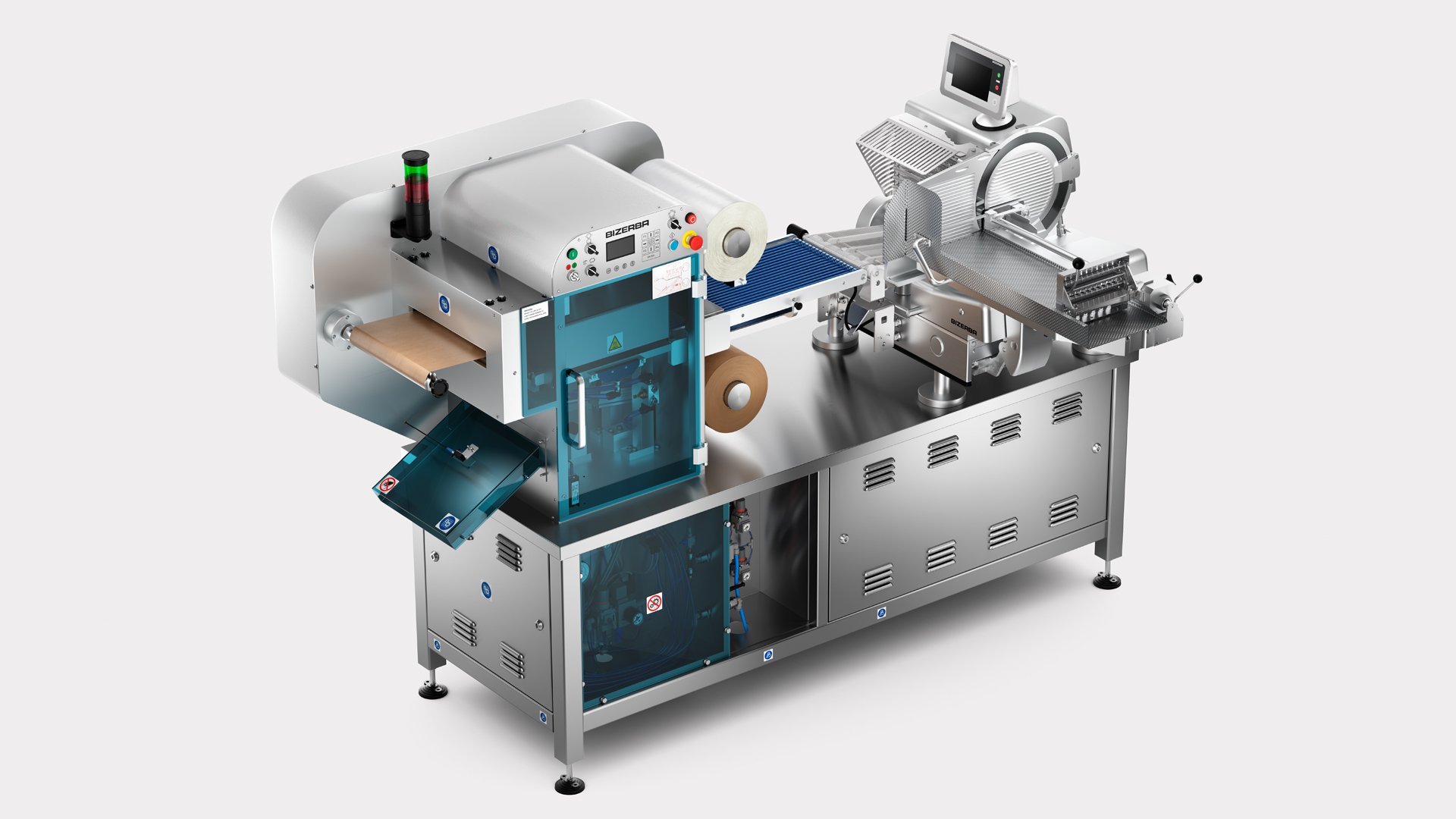

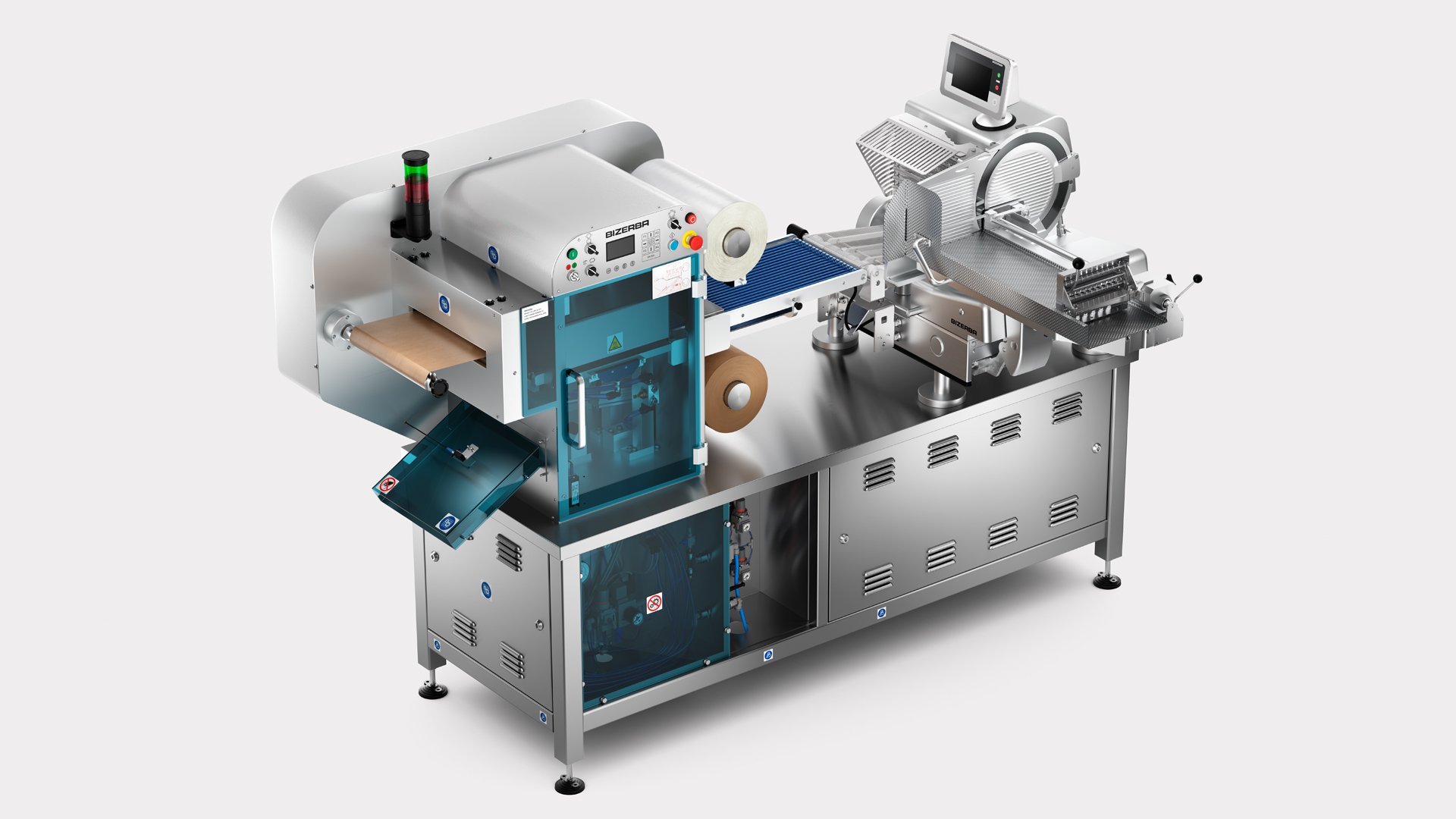

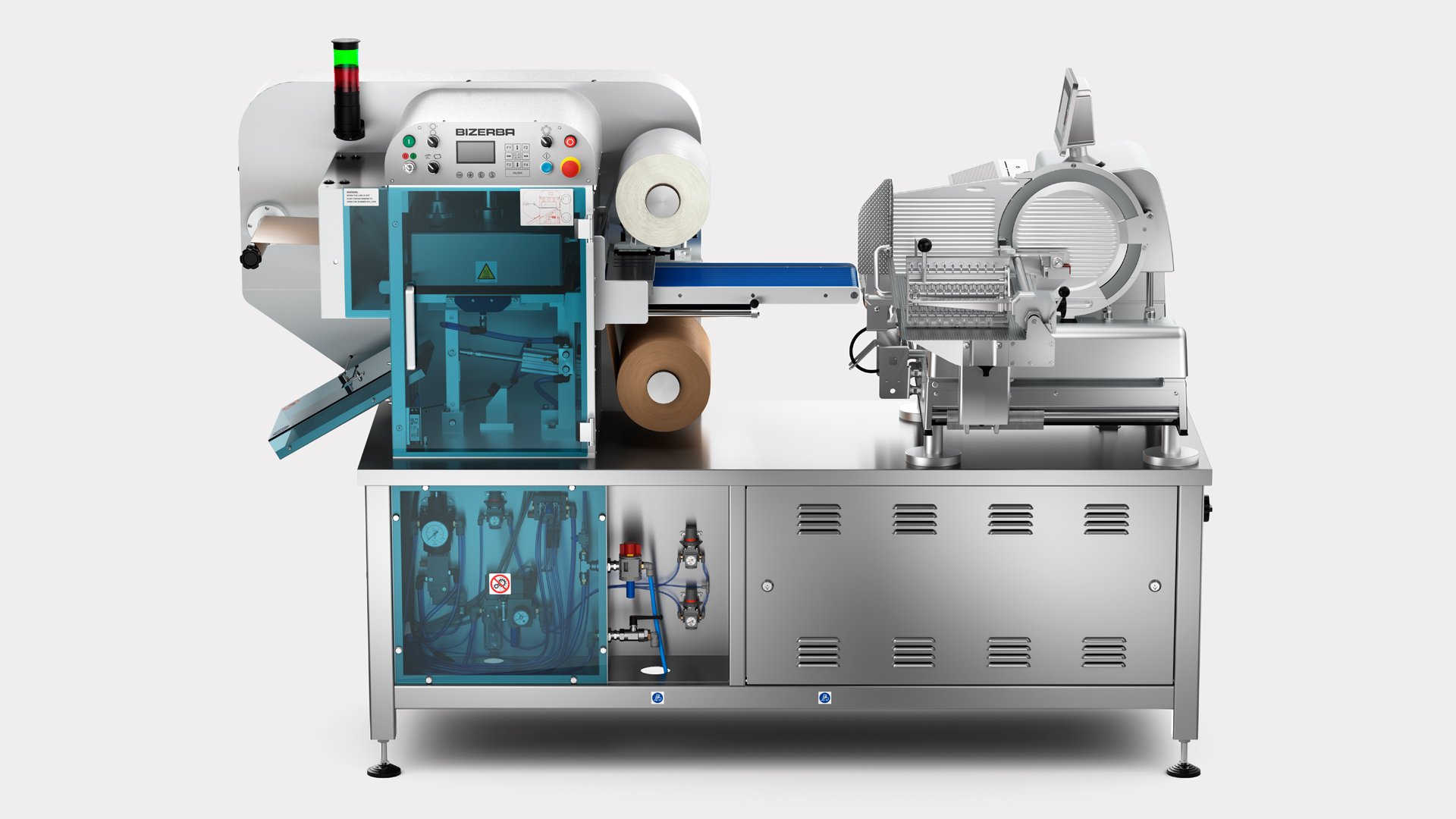

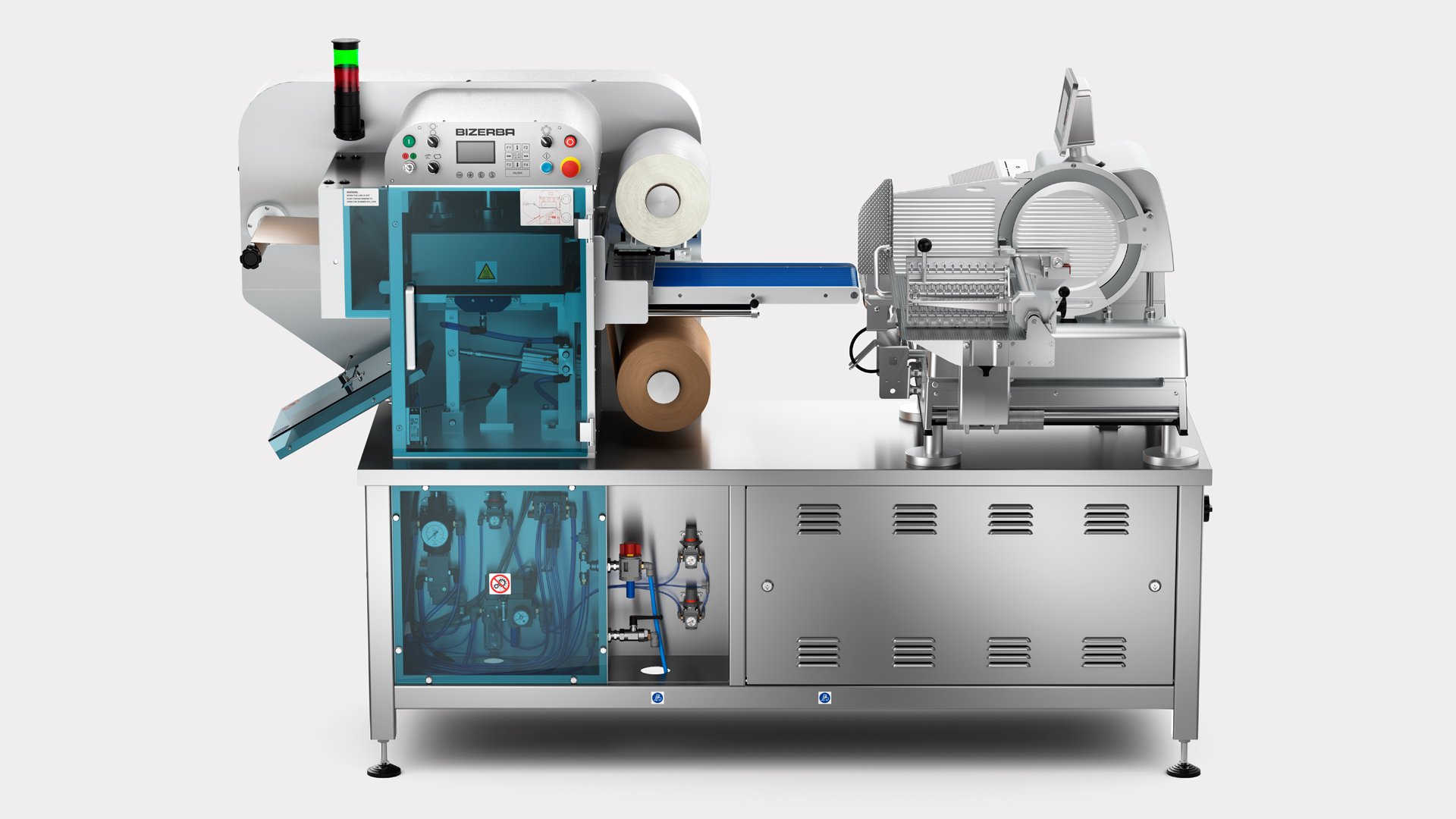

Automatic slicing and packaging machine

LINE PACK VB PLUS packaging machine

The Bizerba LINE PACK VB PLUS thermo-sealing machine is the optimal solution for slicing and packaging cold cuts and cheeses.

The automatic thermo-sealing machine is designed to extend the shelf life of sliced products by packaging them in a protective atmosphere or vacuum, ensuring freshness while preserving a "handcrafted" packaging appearance. Built with the latest technological innovations, this machine minimises maintenance needs and simplifies operation, making it an ideal solution for efficient and reliable packaging processes.

Highlights

Product images and technical information may differ and may not be available in your country.

Areas of Use

Details & Options

For Take Away

Downloads

You can find operating instructions, software updates, licenses, service requests for your personal device in the Bizerba customer portal.

Looks Good?

Please Contact Our Specialists at Any Time

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again