- 170 employees

- 63 million liters of milk per year

- approx. 200 million revenue per year

- 1 location, Kosow Lacki, Poland

Beginnings of OSM Kosów Lacki's cooperation with Bizerba

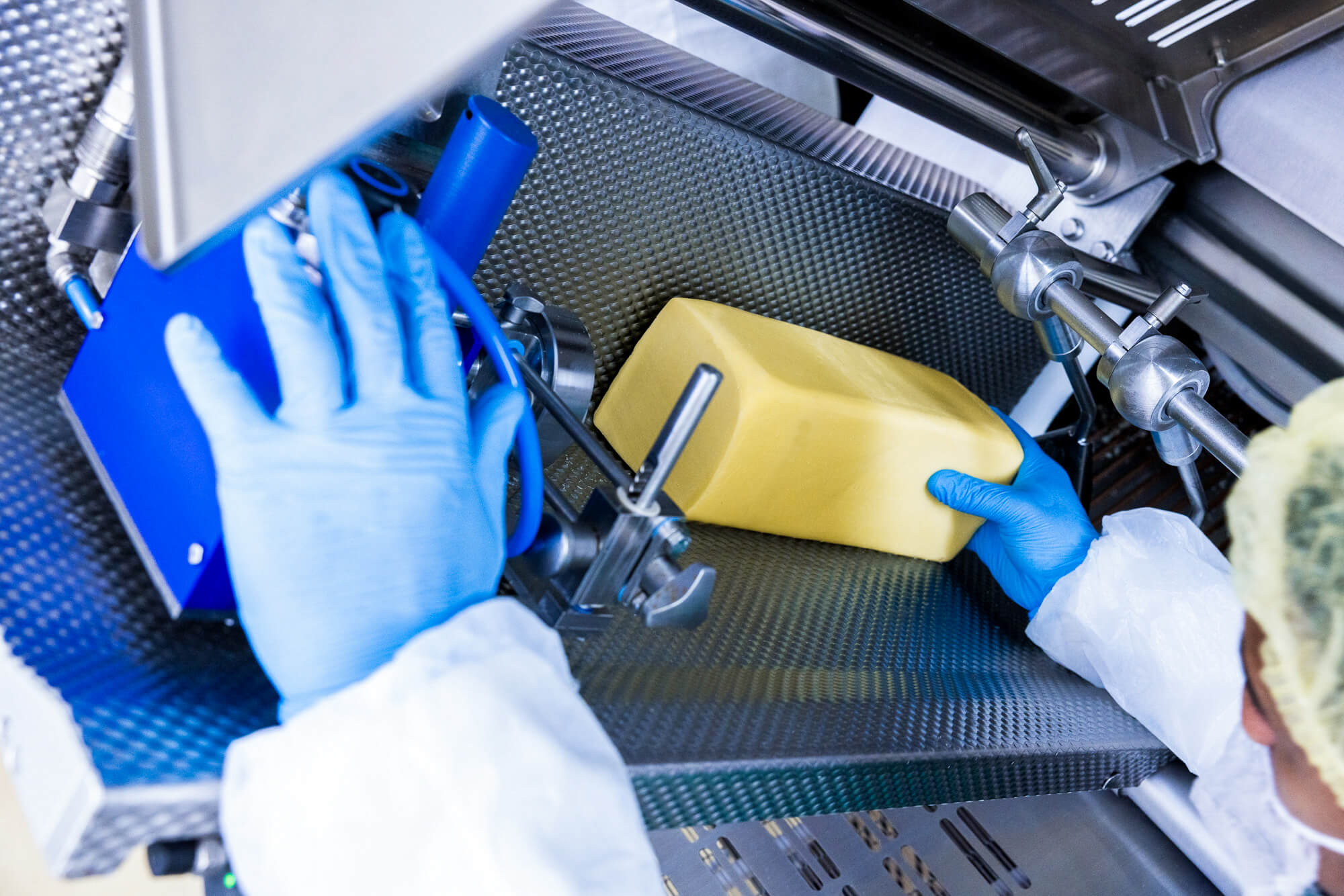

The first Bizerba GLPmaxx 80 label printers with weighbridge appeared at OSM Kosów Lacki in 2013. For that moment, the printers proved to be a sufficient solution. However, over the years, cheese production increased, and thus the need for modern technology and expansion of production lines increased. OSM Kosów Lacki has been investing heavily in the development of its plant since 2017. Investments included the construction of a dairy warehouse and a production and social area. Subsequently, the dairy cooperative purchased a modern cottage cheese packaging machine with a GLM-Emaxx 50 1B weighing and labeling machine and a GLPmaxx 80 printer, a cheese packaging line with an A560 industrial slicer and a GLM-Ievo 70 1B weighing and labeling machine. The dairy cooperative also invested in a cheese-making line with increased capacity to produce cheese in the form of Euroblocks, which involved the purchase of another GLM-Ievo 40 1T weighing and labeling machine.

Yellow, long-ripened, Dutch, smoked cheeses and cottage cheese

Modernity forcing changes in the dairy market

The plant's biggest motivation for investing in machinery is greater purchasing dynamics and greater capacity. OSM Kosów Lacki is moving with the times, betting on a modern production facility, creating comfortable working conditions and putting its staff and employees' needs first.

Special emphasis on pre-packaged goods

In the dairy sector, special demands are placed on prepackaged goods. On the packaging line for fixed-weight products, Bizerba's weighing and labeling system, equipped with a weight control system, continuously checks the net weight of each package to ensure compliance with legal requirements for prepackaged goods.

Flexibility in the choice of labels and labeling method

The most important criteria in selecting equipment are the operating range of the machine, the weighing range, and the ability to use different label and counter label formats depending on the needs of the plant and the expectations of customers.

Demanding end customers

Increasingly demanding end customers, such as retail chains, have their own expectations beyond standard food labeling regulations. Bizerba's systems support the dairy plant in meeting these increasingly high customer demands, speeding up order fulfillment and significantly increasing the efficiency of the weighing process.

Bizerba technologies - comprehensive support for weighing, labeling and packaging processes

Weighing, labeling, confectioning - Bizerba as a reliable partner

Bizerba solutions work at OSM Kosów Lacki in all departments where processes such as weighing and labeling of products are crucial. Bizerba systems work primarily in the cottage cheese plant (the cottage cheese production department), the cheese balancing department (the department for weighing cheeses before packaging, portioning, and labeling), and the cheese slicing department (the department for preparing the product for sale).

Bizerba systems have been tailored to meet the specific needs of the dairy cooperative. In the cheese packing department, where fixed-weight portions are weighed, Bizerba systems and software enable the collection of production data, generation of analysis, trend tracking and detailed statistics on the weighing of packaged products.

Service availability, efficient installation and training

After each purchase and during the commissioning of the systems, Bizerba's service department thoroughly trained staff in the operation of the equipment. Maciej Hermanowski, service technician at Bizerba Poland, deserves a special mention: "We appreciate Mr. Maciej's availability, quick response to our needs, and remote support and telephone consultations at any time. His vast knowledge and service experience enable him to eliminate downtime quickly," says Joanna Zawisza, Chief Technologist.

A new level of production with Bizerba systems

Goals achieved, new challenges

"We have achieved the goals we set for ourselves in production, but we are not resting on our laurels. We are working on a new project to purchase new equipment and integrate it into one coherent system. This way we want to acquire, analyze and report production data and accurately account for production," says Joanna Zawisza, Chief Technologist.

Demanding end customers

Increasingly demanding end customers, such as retail chains, have their own expectations beyond standard food labeling regulations. Bizerba's systems support the dairy plant in responding to the increasingly high demands and expectations of customers. The weighing and labeling systems speed up order processing and significantly increase the efficiency of the weighing process.

OSM Kosów Lacki in numbers

Bizerba solutions at OSM Kosów Lacki

Sounds good?

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again