- 53 years in the industry

- 2002: launch of Meat Plant in Dobrzyca, Poland

- Fresh and frozen poultry meat

Let’s count

From line to table. Safety, built in.

Minimising the risk of contamination

In modern poultry processing, ensuring food safety and fully eliminating the risk of contamination are essential. Hermetically packaged products must move through production lines free from metallic foreign bodies that could endanger consumers or compromise the company’s reputation.

Precision and complete inspection of every package

In large-scale production, accurate weighing alone is not enough. Correct labelling and full traceability are equally critical. Each tray must meet precise weight requirements and carry the correct label, while maintaining maximum line efficiency.

Detection, weighing and labeling by Bizerba provides control at every stage

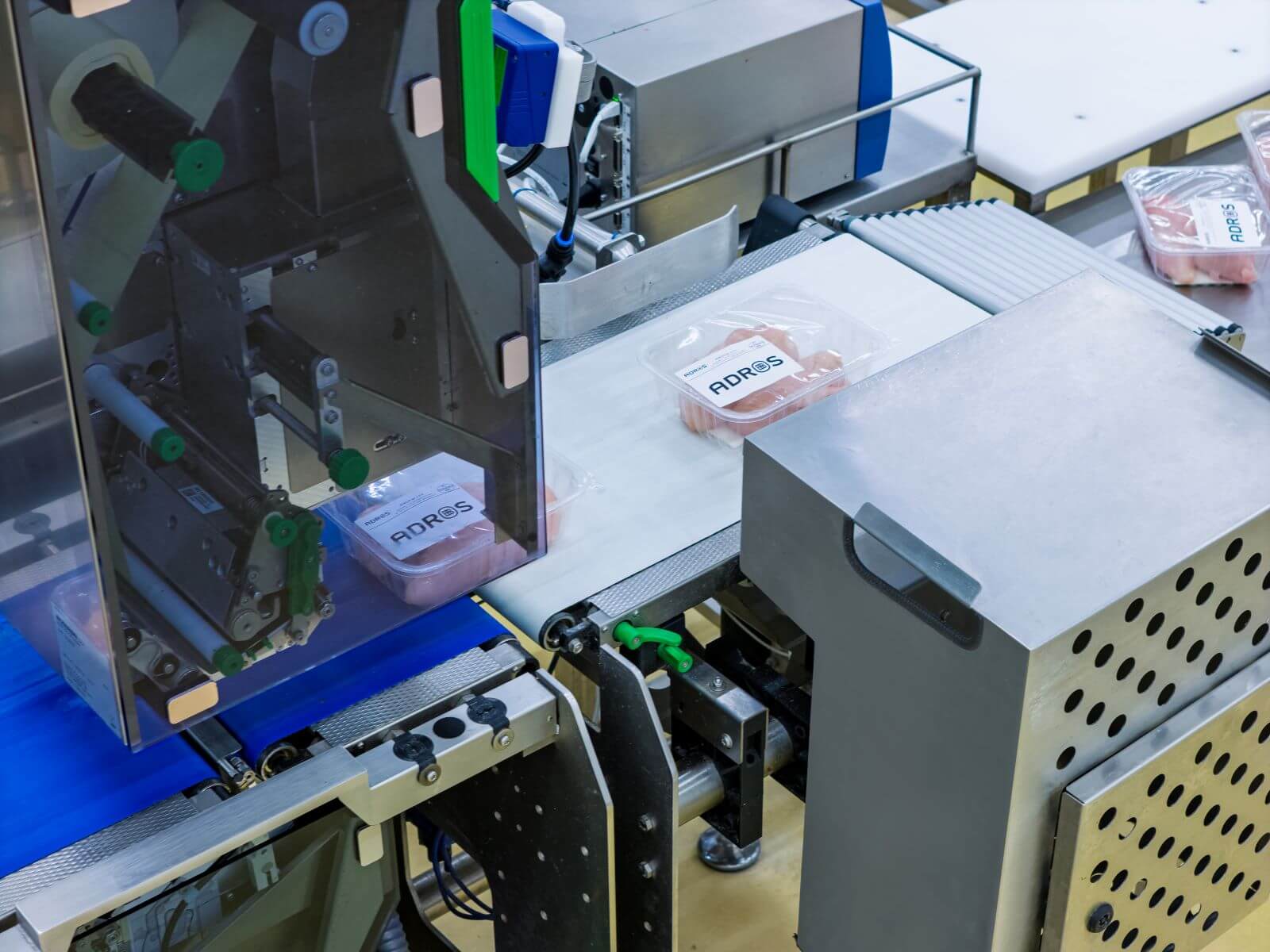

Adros Meat Plant has implemented Bizerba iMD pro metal detectors on its transport lines. Thanks to their high sensitivity, the systems reliably detect even minimal contamination and automatically reject affected products. Fully integrated into the production line, the rejection process is repeated automatically, ensuring the safety of the entire product batch. This approach enables the company to maintain the highest standards of hygiene and food safety.

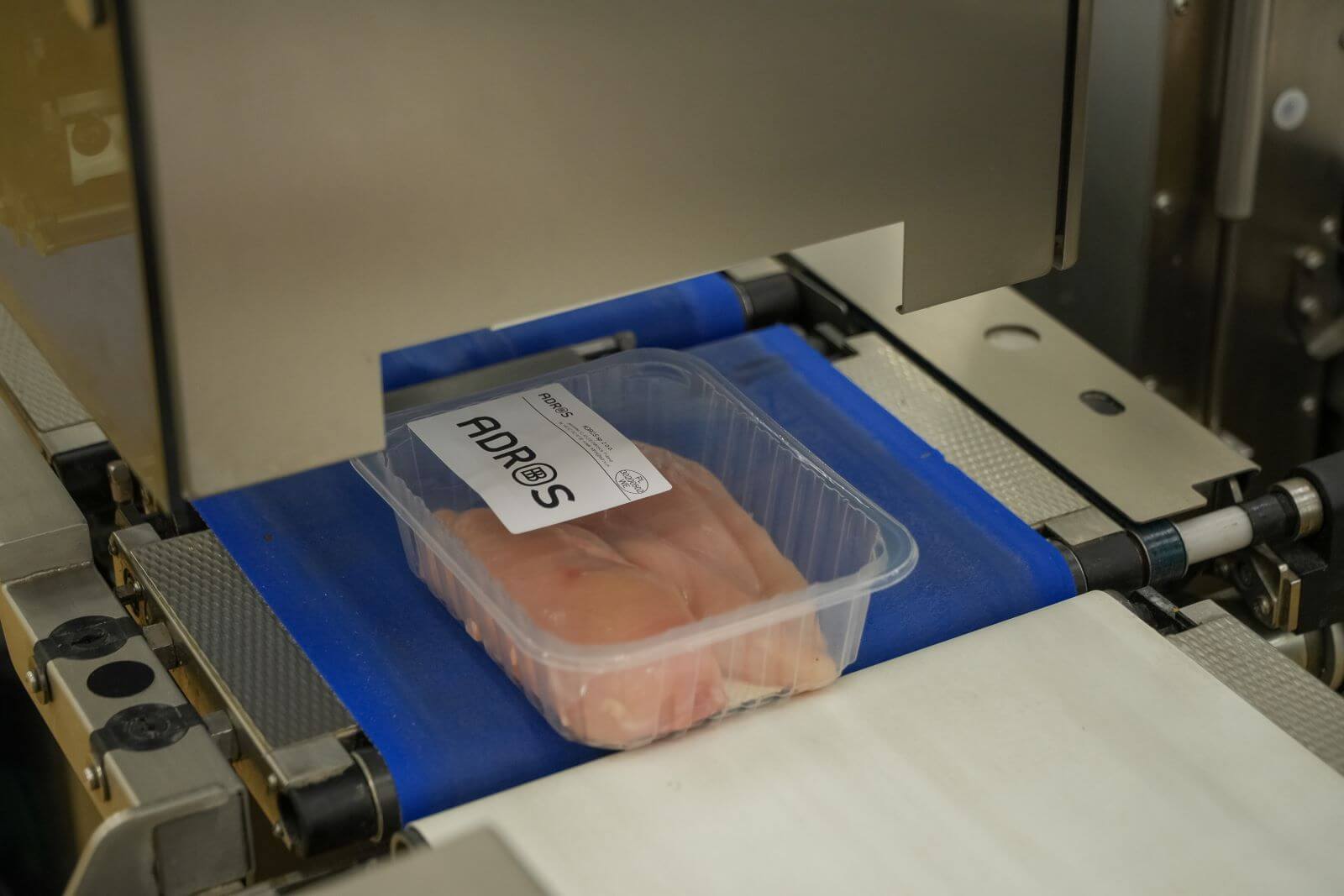

In addition, the meat plants use Bizerba GLM-I G5 1T1B weighing and labeling systems, which ensure precise weighing, fast label printing and accurate application on each package. The systems are intuitive to operate, while all relevant data is displayed on screens and stored in system logs, enabling full product traceability. The Bizerba solution delivers consistent processes, compliance with market requirements and high production efficiency.

Bizerba GLPmaxx 160 label printers further support clear and reliable printing of summary labels, ensuring seamless traceability across the entire supply chain.

Quality control that protects your brand reputation

Thanks to Bizerba’s integrated solutions, Adros Meat Plant has achieved full control over product safety and quality at every stage of production. Reliable contamination detection, precise weighing and market-compliant labeling ensure consumer safety and strengthen customer confidence. Automated processes, full traceability and high line efficiency enable the plant to scale production without compromise, while safeguarding the brand and its reputation.

Bizerba solutions at Adros Meat Plant

Any questions?

Your message is on it’s way

The form was sent successfully

Oops, something went wrong here

An error occurred when sending the form. Please try again