Where Retail, Industry, and Labeling Come Together

160 Years Bizerba:

Celebrating Precision

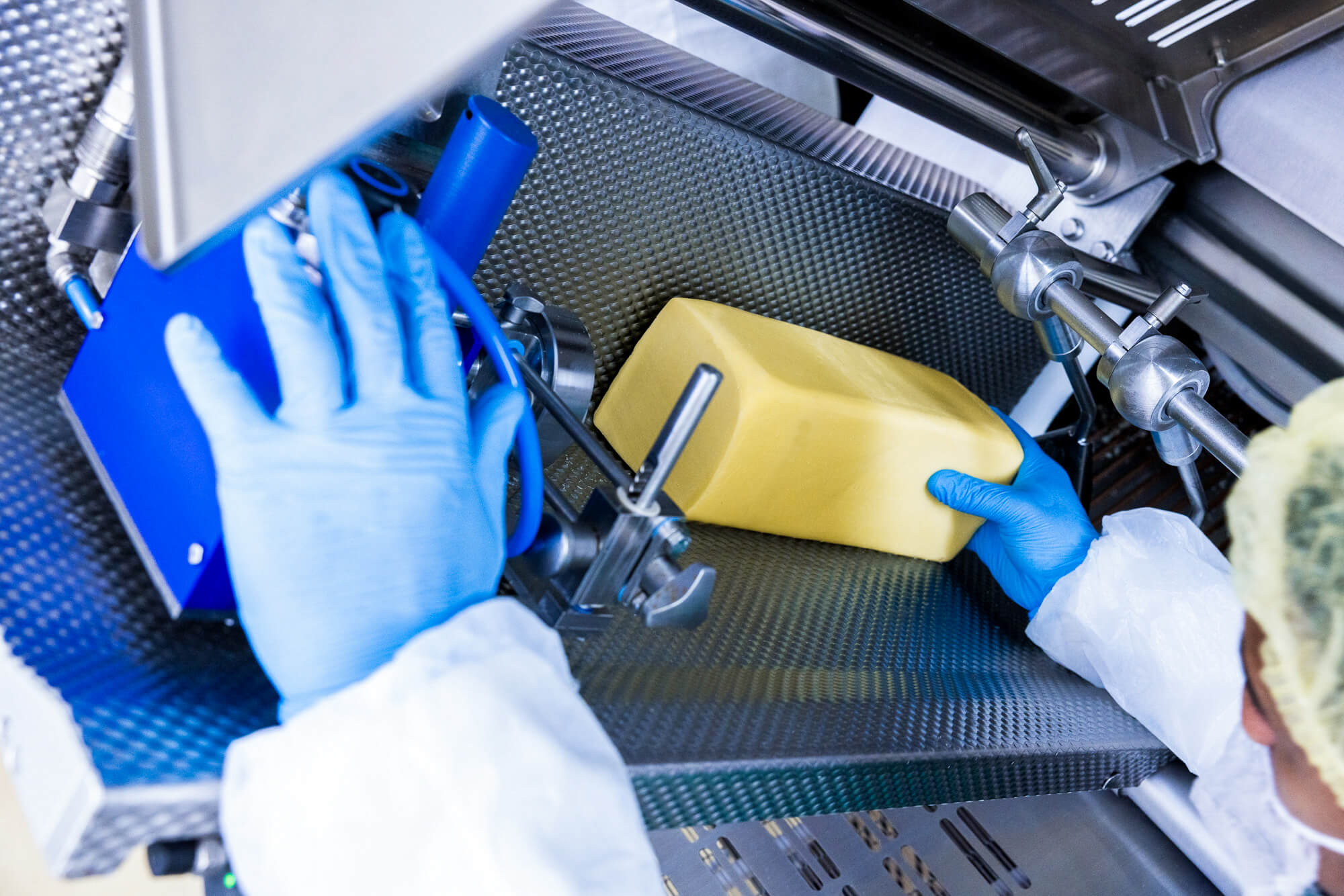

Revolutionize Your Packaging with the B3 Automatic Weigh-Wrap System

Discover solutions tailored to your needs

Welcome to a world where top-quality solutions are crafted to meet your unique needs. Your company deserves a tailor-made plan, and we're here to be your partner in designing the perfect combination that propels your economic success. Discover the unparalleled difference we offer, with a global portfolio that sets us apart, innovative solutions that break new ground, and a dedicated team that greets you with: 'What do you need?' Join us on this extraordinary journey and unlock the possibilities that set you apart from the rest.

Real people. Real opportunities.

Bizerba is a growing, innovative global player that offers a value-oriented, family-like environment – with unlimited development opportunities domestically and abroad, plus a wide range of benefits that will enrich your (working) life and make it easier.